sustainable-packaging

Sustainable packaging and

climate-friendly materials

climate-friendly plastics and other materials.

What is sustainable packaging?

The term “sustainability” has been used since the 1980s (Source: Packwise) and has more recently become an even bigger issue in our daily lives. Sustainable development is about reducing climate impacts and promoting a more balanced use of resources. It is about using, reusing and recycling our materials in a way that protects the environment as much as possible. One way we can help protect the environment is through our production of packaging. There are many types of packaging, all of which affect the environment to varying degrees. It is necessary to consider material selection, production and recyclability when using and producing packaging. In addition, sustainable packaging can be a way to protect the environment and promote a greener transition.

Types of plastic

Virgin plastic

Virgin Plastic is plastic resin produced directly from petrochemical feedstocks that have never been used or processed before – such as crude oil or natural gas (Source: Packwise). In other words, it is plastic that does not contain recycled packaging. The fact that Virgin Plastic is constructed from non-recycled materials enhances its quality and durability.

Ocean Waste Plastic

Ocean Waste Plastic is a concept to eliminate the man-made plastic floating around out in our oceans. Plastic pollution in the world’s oceans is among the greatest environmental challenges we face today. Around 300 million tons of plastic are produced every year, and at least 14 million tons of this ends up in our oceans, harming marine biodiversity and marine species (Source: IUCN).

Ocean Waste Plastic could be one of the solutions to this challenge. By collecting the plastic from the oceans and recycling the material, we remove it from nature while giving it new life, and be a part of sustainable packaging.

Bioplastic

Bio-plastic is a term that covers several types of bio-based plastic manufacturing.

Bio-based plastic:

The production of conventional plastics uses large amounts of oil or natural gas as raw materials. In contrast, bio-based plastics are made from biological material such as maize, sugar cane and hemp, making the production of the material more environmentally friendly. In addition, bio-based plastics can also be reused and recycled several times alongside conventional plastics of the same type and be a part of the sustainable packaging. Bio-PET plastics can therefore be used alongside conventional PET plastics, for example.

Biodegradable plastic:

As well as being created from biomass, biodegradable plastics can also be made from gas, oil or a mixture of these. The advantage of biodegradable plastic is that it can be broken down. This means that the material is removed from our environment by micro-organisms such as fungi or bacteria, which convert the plastic into biomass, CO2, water or methane. You can also read more about the difference between bio-based and biodegradable plastics in the Ministry of Environment’s 2020 report. This type of sustainable packaging can help us make packaging which is less damaging to the environment.

Biocompostable plastic:

Biocompostable plastic goes a step further from biodegradable plastic, as this type of plastic must meet a number of criteria in order to be labelled as sustainable packaging. The plastic must degrade at the same rate as paper, and in addition it must degrade into materials that are gentler on the environment. This could be CO2, biomass, water, or other organic material.

Oxo-degradable plastic:

Oxo-degradable plastics contain small amounts of metal salts. The plastic degrades when it encounters oxygen, as this process speeds up the natural degradation of the material. Oxo-degradable plastics are often used in garbage and carrier bags and marketed as a solution to plastic pollution. However, several studies show that this is not the case – including the World Economic Forum’s 2016 report.

A sustainable approach

Sustainability is a term that covers many things – recycling, for example, is considered to be sustainable. If producers and consumers focus more on recycling raw materials and packaging, fewer brand-new products will be produced, reducing CO2 emissions. Recycling is thus part of a circular economy, which is much more sustainable than a linear economy.

What is a circular economy?

For many years our economy has been linear, meaning that we have extracted raw materials to make products that have then been used and discarded.

The circular economy is about changing this view of the lifetime of our products, so that they can be recycled instead of the continuous production of new ones. In other words, we need to be better at reusing and recycling rather than throwing out and producing new. This will help to create more sustainable production.

On the right you can see an illustration of what the circular economy could look like:

Developing sustainable packaging.

Producing and developing sustainable packaging can be a challenge. So, it is beneficial to find a partner with expertise in the area. This will help you produce sustainable packaging and environmentally friendly products, ensuring that both you and your customers get sustainable packaging that focuses on protecting the environment.

At Packwise, we can help you with the design, development, and production of your sustainable and environmentally friendly packaging.

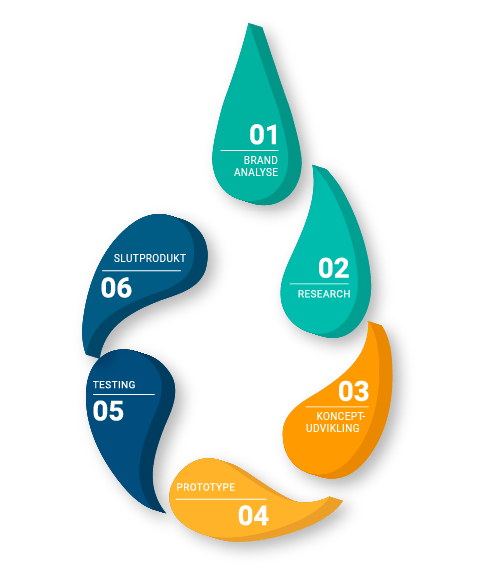

The model on the left illustrates Packwise‘s design process from start to finish. You can read more about Packwise by clicking on the button below, which will take you to the Packwise website

E-books on sustainable packaging and eco-friendly plastics:

We have gathered our knowledge in a series of e-books that can give you even more knowledge about sustainable packaging and eco-friendly plastics. By clicking on the link below, you will be taken to the Packwise website where you can download your own free copy of the e-books. The packaging company Packwise has years of experience in the development and production of sustainable packaging and climate-friendly packaging.